ONE-TRACK MOTORIZED SCREEN

Why One-Track

ONE-TRACK MOTORIZED SCREEN

Why One-Track

MAXFORCE PROVEN PROTECT

Engineered For Excellence

For nearly two decades, Fenetex has manufactured hurricane screens to meet the most demanding building code, the High Velocity Hurricane Zone of Miami-Dade. The MaxForce track is our newest version of the fixed track we have used with great success for high wind applications all over the globe.

The benefits of a fixed track are unmatched strength - this is important when designing a screen system for hurricanes. When you want the strongest system available, and a proven veteran of many hurricanes, the Fenetex MaxForce Hurricane Track is your best choice.

MAXFORCE PROVEN PROTECT

Engineered For Excellence

For nearly two decades, Fenetex has manufactured hurricane screens to meet the most demanding building code, the High Velocity Hurricane Zone of Miami-Dade. The MaxForce track is our newest version of the fixed track we have used with great success for high wind applications all over the globe.

The benefits of a fixed track are unmatched strength - this is important when designing a screen system for hurricanes. When you want the strongest system available, and a proven veteran of many hurricanes, the Fenetex MaxForce Hurricane Track is your best choice.

FENETEX THE #1 MOTORIZED HURRICANE SCREEN

Contact A+ Certified One-Track Screen Dealer Today...

FENETEX THE #1 MOTORIZED

HURRICANE SCREEN

Contact A+ Certified

One-Track Screen

Dealer Today...

ONE-TRACK HURRICANE SCREENS

Engineering Features

No blowouts. No rewraps. No frustration.

One-Track is the only retractable screen system on the market designed to stay locked in the track—even in high winds. Smart motor senses resistance and adjusts seamlessly, allowing self-correction when the screen encounters an obstacle: Fewer snags, fewer jams, and fewer costly service calls.

No Zipper. No Cable. Just Simple Deployment

Fenetex pioneered Keder-edge technology in motorized screens, delivering unmatched durability and simplicity. Borrowed from sailboat rigging, this system eliminates zippers, cables, and exposed hardware—ensuring smooth, reliable operation every time.

Heavy Duty

The One-Track weight bar is engineered for strength—and built to hold its ground. Pound for pound, it’s the heaviest and most robust weight bar in the industry. This ensures proper screen tension, flawless deployment, and maximum stability in high wind zones. —limited flex, no failure.

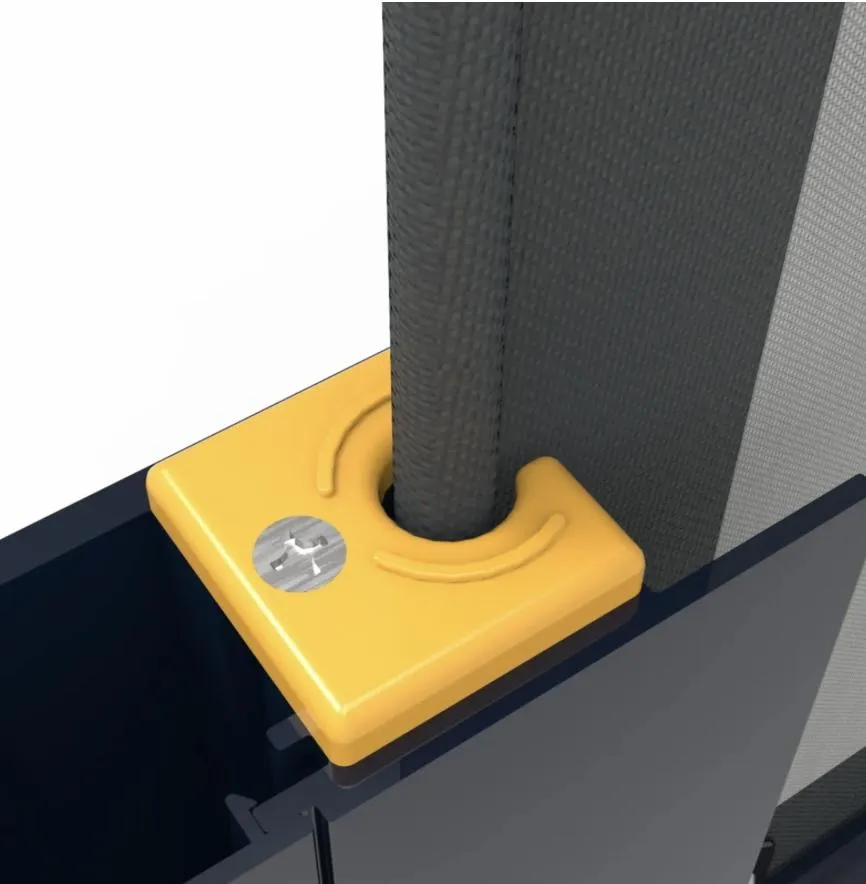

Reinforced Corners

One-Track’s heavy-duty weight bar isn’t just strong. It’s smart. Reinforced corners and integrated tie-ins create a unified structure that acts like a solid wall of protection when deployed. Made from high-strength nylon, this bar absorbs impacts while maintaining structural integrity.

ONE-TRACK HURRICANE SCREENS

Engineering Features

No blowouts. No rewraps. No frustration.

One-Track is the only retractable screen system on the market designed to stay locked in the track—even in high winds. Smart motor senses resistance and adjusts seamlessly, allowing self-correction when the screen encounters an obstacle: Fewer snags, fewer jams, and fewer costly service calls.

No Zipper. No Cable. Just Simple Deployment

Fenetex pioneered Keder-edge technology in motorized screens, delivering unmatched durability and simplicity. Borrowed from sailboat rigging, this system eliminates zippers, cables, and exposed hardware—ensuring smooth, reliable operation every time.

Heavy Duty

The One-Track weight bar is engineered for strength—and built to hold its ground. Pound for pound, it’s the heaviest and most robust weight bar in the industry. This ensures proper screen tension, flawless deployment, and maximum stability in high wind zones. —limited flex, no failure.

Reinforced Corners

OneTrack’s heavy-duty weight bar isn’t just strong. It’s smart. Reinforced corners and integrated tie-ins create a unified structure that acts like a solid wall of protection when deployed. Made from high-strength nylon, this bar absorbs impacts while maintaining structural integrity.

HEADACHE-FREE

Exclusive self-tensioning system eliminates 99.9% of screen issues. No track adjustments, broken zippers,or dislodged screens.

WHISPER QUIET

Springs ensure even tension for peaceful patio relaxation without unwanted screen noise.

HURRICANE STRONG

Our MagForce tracks and advanced hybrid ballistic fabrics withstand 150+ mph winds. Approved by Florida Building Commission for hurricane zones. Lab and real-world tested.

BUILT TO LAST

We use marine-grade materials such as powder-coated aluminum, UV-protected nylons, stainless steel fasteners, and premium fabrics. Resists corrosion, rust, and screen failure.

COST-SAVING

Exterior shade screens reduce cooling bills and Fenetex hurricane screens reduce insurance premiums in hurricane zones.

SMART CONTROLS

Control Fenetex screens via remote and

phone or integrate with popular home automation systems for advanced

capabilities.

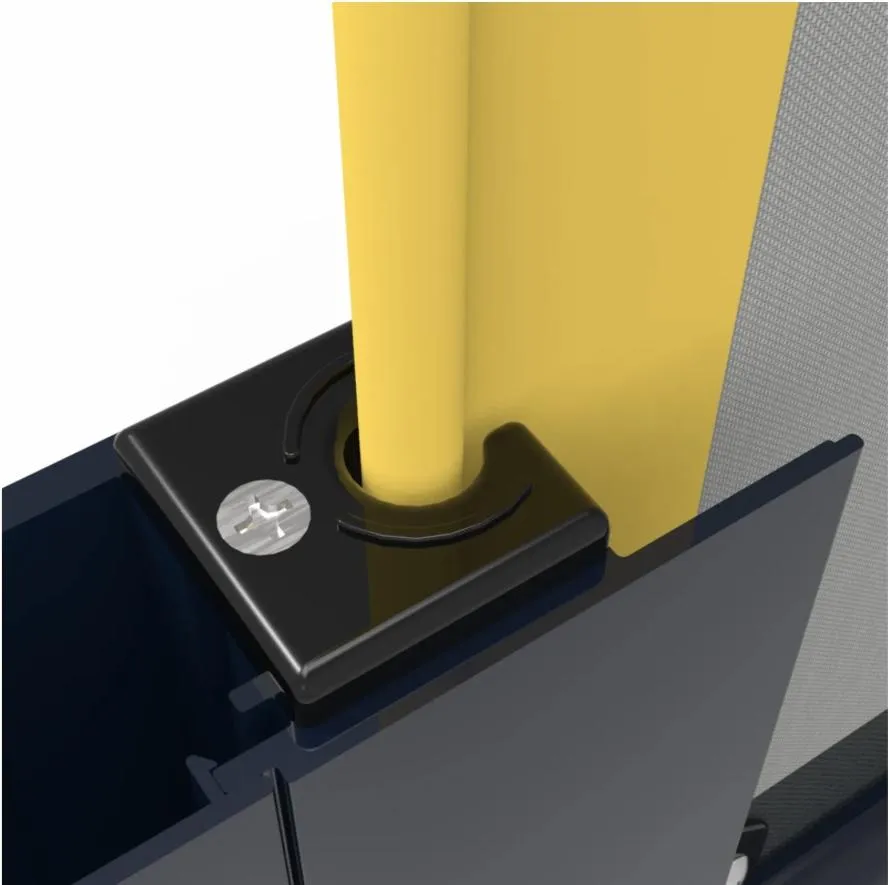

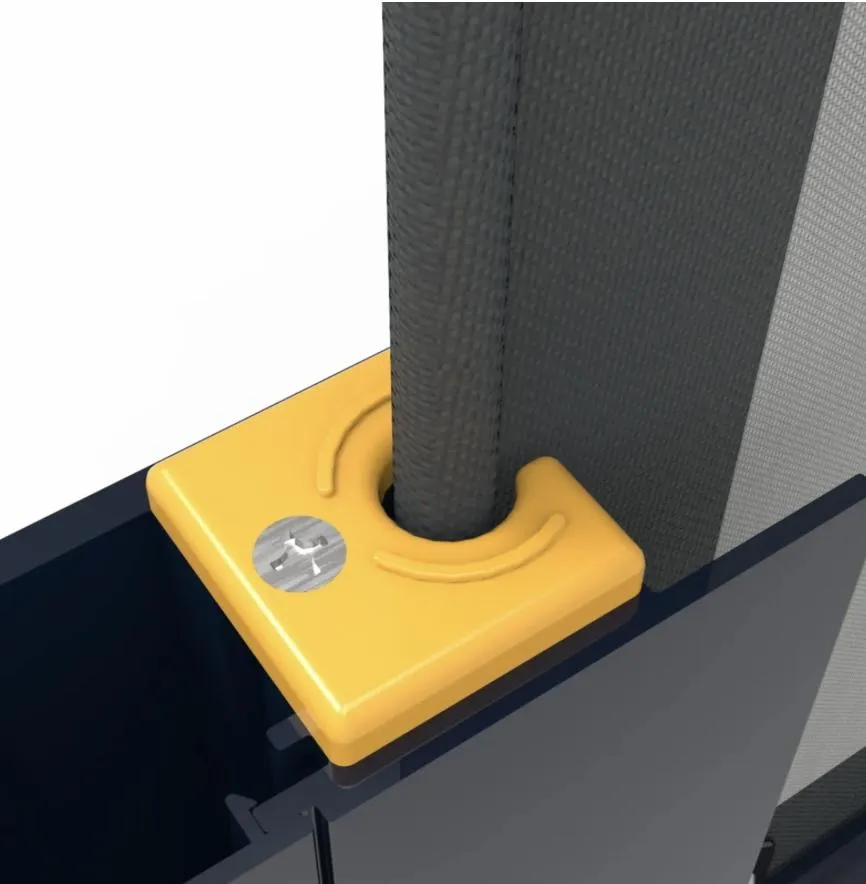

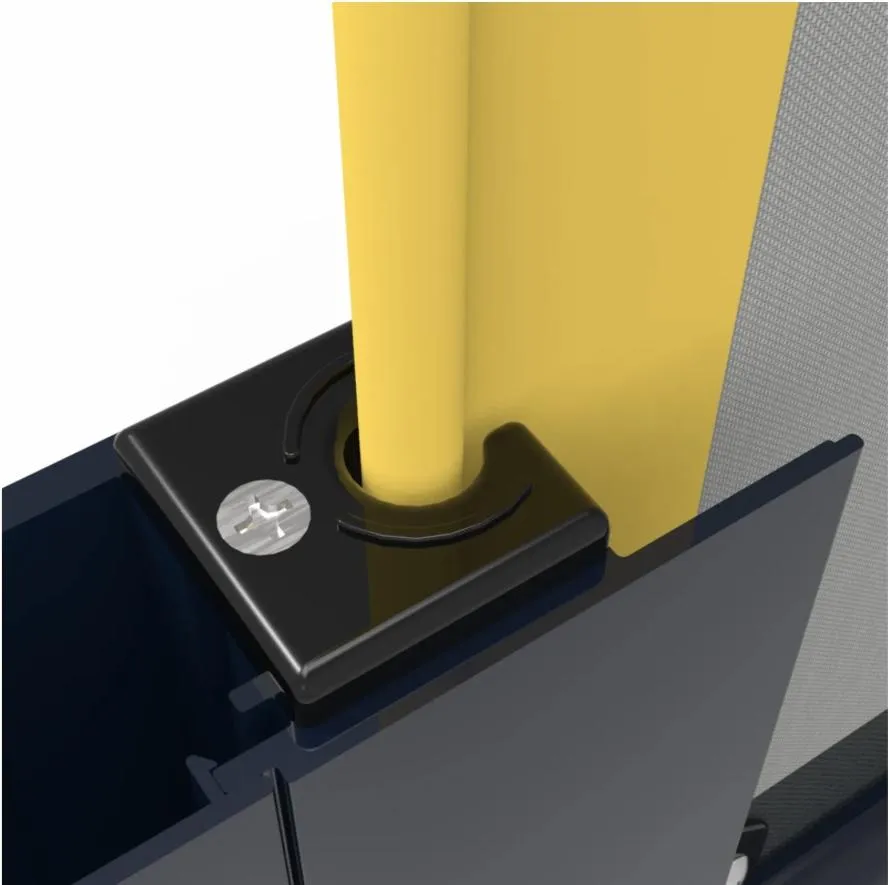

SECURE TRACK

MaxForce Fix Hurricane Track holds

firm under extreme loads

MAX CORROSION PROTECTION

Powder Coated Aluminum Protects your investment from exposer and corrosion.

HEAVY-DUTY DESIGN

Our screens are designed to withstand the extreme. High wind, Rain, or Shine, Dust Dirt, Dander, it doesn't matter. MaxForce Cover it all.

CUSTOM-MADE SCREENS

Tailor-made screens with vast color,

fabric, and system options. Custom paint color and fabric matching are available.

LIFETIME WARRANTY

No other company can stand behind their products like Fenetex can because no other company can match our quality.

FENETEX THE #1 MOTORIZED

HURRICANE SCREEN

Contact A+ Certified

One-Track Screen

Dealer Today...

HEADACHE-FREE

Exclusive self-tensioning system eliminates 99.9% of screen issues. No track adjustments, broken zippers,or dislodged screens.

WHISPER QUIET

Springs ensure even tension for peaceful

patio relaxation without unwanted

screen noise.

HURRICANE STRONG

Our MagForce tracks and advanced hybrid ballistic fabrics withstand 150+ mph winds. Approved by Florida Building Commission for hurricane zones. Lab and real-world tested.

BUILT TO LAST

We use marine-grade materials such as powder-coated aluminum, UV-protected nylons, stainless steel fasteners, and premium fabrics. Resists corrosion, rust, and screen failure.

COST-SAVING

Exterior shade screens reduce cooling bills and Fenetex hurricane screens reduce insurance premiums in hurricane zones.

SMART CONTROLS

Control Fenetex screens via remote and

phone or integrate with popular home automation systems for advanced

capabilities.

SECURE TRACK

MaxForce Fix Hurricane Track holds

firm under extreme loads

MAX CORROSION PROTECTION

Powder Coated Aluminum Protects your investment from exposer and corrosion.

HEAVY-DUTY DESIGN

Our screens are designed to withstand the extreme. High wind, Rain, or Shine, Dust Dirt, Dander, it doesn't matter. MaxForce Cover it all.

CUSTOM-MADE SCREENS

Tailor-made screens with vast color,

fabric, and system options. Custom paint color and fabric matching are available.

LIFETIME WARRANTY

No other company can stand behind their products like Fenetex can because no other company can match our quality.

FENETEX THE #1 MOTORIZED HURRICANE SCREEN

Contact A+ Certified One-Track Screen Dealer Today...

ONE-TRACK

Ready For Life's Storms

ONE-TRACK HURRICANE SCREEN SYSTEM

A Certified, Tested System...

The MaxForce Hurricane Screen System meets or exceeds Miami-Dade and Florida Building Code requirements—the toughest hurricane codes on earth—for roll-down hurricane screens. Rated for the 185 MPH wind zone, and with real-world and certified testing. With spans of up to 24 feet, they exceed performance criteria for all local and International Building Codes.

ONE-TRACK

Ready For Life's Storms

ONET-RACK HURRICANE SCREEN SYSTEM

A Certified, Tested System...

The MaxForce Hurricane Screen System meets or exceeds Miami-Dade and Florida Building Code requirements—the toughest hurricane codes on earth—for roll-down hurricane screens. Rated for the 185 MPH wind zone, and with real-world and certified testing. With spans of up to 24 feet, they exceed performance criteria for all local and International Building Codes.

FENETEX THE #1 MOTORIZED HURRICANE SCREEN

Contact A+ Certified One-Track Screen Dealer Today...

FENETEX THE #1 MOTORIZED

HURRICANE SCREEN

Contact A+ Certified

One-Track Screen

Dealer Today...

THE FENETEX DIFFERENCE

One-Track Hurricane Screen

MaxForce Hurricane Screens, powered by our patented MagForce system, meet the toughest standards—including HVHZ certification in Miami-Dade and Broward. They last longer, resist more, and do more than any screen on the market—proven protection without compromise.

MaxForce Hurricane Screens —Delivers 365 days of perfect protection, rain or shine, on your patio and lanai. With the push of a button or a tap on the mobile app, your patio is storm-ready— furniture and openings fully protected in seconds.

MaxForce Hurricane Screens fabric blocks up to 95% of the sun’s damaging UV-rays while shielding against wind, rain, insects, dust, and debris. It also helps reduce heat and lower energy costs by limiting solar exposure—comfort and protection in one smart solution.

Like all Fenetex products, our MaxForce Hurricane Screens are highly customizable and built to order—made to fit your exact openings. No guesswork, no compromises—just precision-fit protection tailored to your space.

Pair our retractable MaxForce Hurricane Screens with other Fenetex screens for customized and independent solutions. Each screen operates independently, giving you the protection you want when you need it.

MaxForce Hurricane Screens offer built-in privacy without blocking your view. Like a two-way mirror, you can see out—but neighbors and passersby can not see in. It provides the perfect blend of openness and seclusion, day or night.

THE FENETEX DIFFERENCE

One-Track Hurricane Screen

MaxForce Hurricane Screens, powered by our patented MagForce system, meet the toughest standards—including HVHZ certification in Miami-Dade and Broward. They last longer, resist more, and do more than any screen on the market—proven protection without compromise.

MaxForce Hurricane Screens —Delivers 365 days of perfect protection, rain or shine, on your patio and lanai. With the push of a button or a tap on the mobile app, your patio is storm-ready— furniture and openings fully protected in seconds.

MaxForce Hurricane Screens fabric blocks up to 95% of the sun’s damaging UV-rays while shielding against wind, rain, insects, dust, and debris. It also helps reduce heat and lower energy costs by limiting solar exposure—comfort and protection in one smart solution.

Like all Fenetex products, our MaxForce Hurricane Screens are highly customizable and built to order—made to fit your exact openings. No guesswork, no compromises—just precision-fit protection tailored to your space.

Pair our retractable MaxForce Hurricane Screens with other Fenetex screens for customized and independent solutions. Each screen operates independently, giving you the protection you want when you need it.

MaxForce Hurricane Screens offer built-in privacy without blocking your view. Like a two-way mirror, you can see out—but neighbors and passersby can not see in. It provides the perfect blend of openness and seclusion, day or night.

FENETEX THE #1 MOTORIZED HURRICANE SCREEN

Contact A+ Certified One-Track Screen Dealer Today...

FENETEX THE #1 MOTORIZED

HURRICANE SCREEN

Contact A+ Certified

One-Track Screen

Dealer Today...

THE FENETEX DIFFERENCE

One-Track Hurricane Screen

AMERICAN INGENUITY

Made in the USA.

Proudly Made in the USA—every Fenetex screen is built with American strength, precision, and pride. From the smallest components to the final assembly, our materials are sourced and manufactured right here in the United States. No outsourcing. No compromises. Just hardworking Americans protecting American homes with the toughest screen system on the market.

THE FENETEX DIFFERENCE

One-Track Hurricane Screen

AMERICAN INGENUITY

Made in the USA.

Proudly Made in the USA—every Fenetex screen is built with American strength, precision, and pride. From the smallest components to the final assembly, our materials are sourced and manufactured right here in the United States. No outsourcing. No compromises. Just hardworking Americans protecting American homes with the toughest screen system on the market.

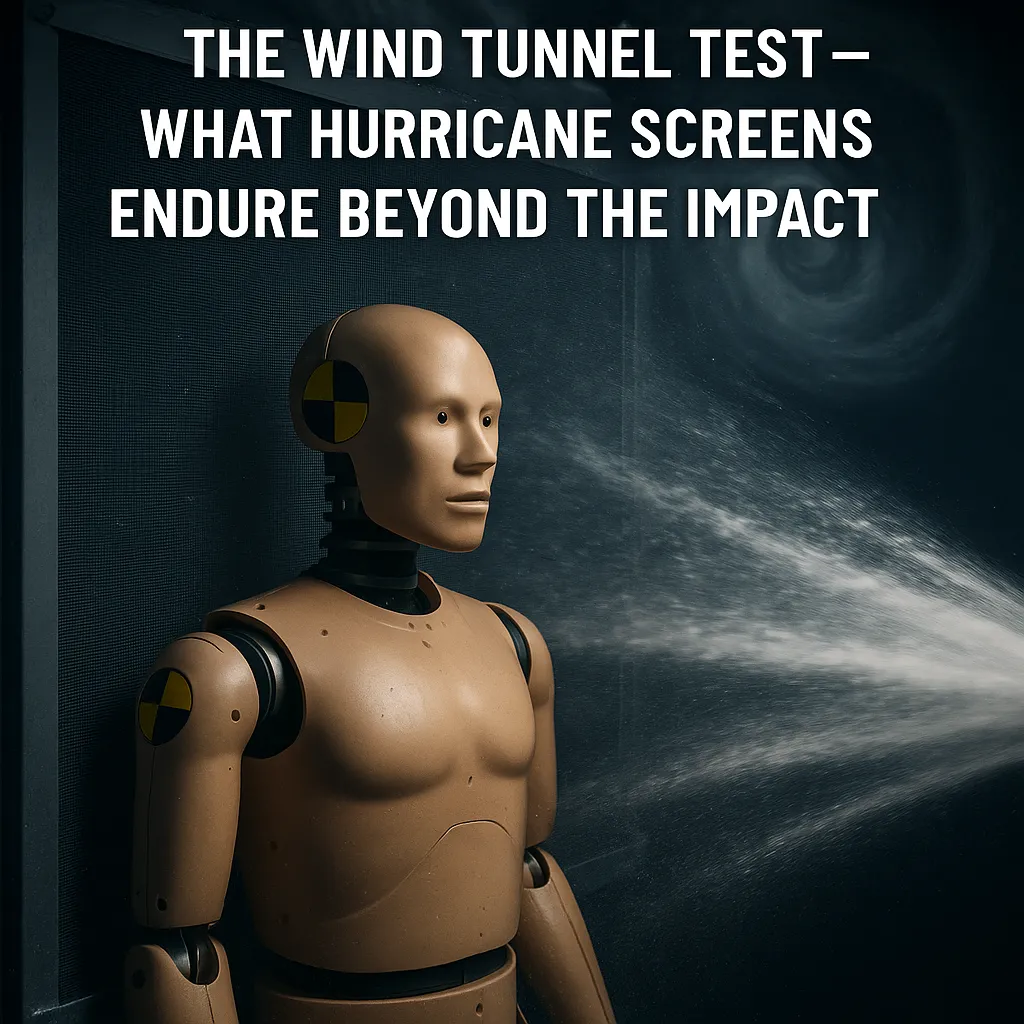

Beyond Impact: Why Hurricane Screens Must Pass the Wind Load Test

Impact is the Wrecking Ball, Wind Pressure is the Hurricane’s Breath.

You’ve seen how hurricane screens get pounded like car hoods in a crash test. But here’s the next question: What comes in the wake of the hit — when the storm continues to push? That’s where wind pressure testing comes in. The same way engineers of automobiles run tests to see how doors will fare in a rollover, screen makers simulate hours of hurricane-level winds to determine whether their product buckles, bows, buckles or blows apart. The standard? TAS 202 or ASTM E330. Consider it a wind tunnel test for your screen.

🚗 Analogy Time: Crash Test Dummies in a Wind Tunnel Think about it:

You take a car, put it in a wind tunnel and then, for 30-minute increments, you hit it with hurricane gusts, not a brief 5-second burst. That’s what TAS 202 simulates: Positive pressure: pushing the screen in, as the wind would the front of your house.

Negative pressure: sucking the screen outward (wind blowing past and pulling and from behind; this is roof-ripping wind). Your screen needs to do more than survive an impact — it needs to continue to perform intense pressure. No fluttering. No blowouts. No detachment from the frame.

🔬 Deconstructing TAS 202 / ASTM E330 TAS 202 is the reference cited by the Florida Building Code for testing of wind pressure.

ASTM E330 is the domestic equivalent of the structural performance of windows, doors and hurricane screens. Here’s what they test:

Air pressure loading corresponding to Category 5 hurricane winds (or custom design pressures).

Alternating positive and negative pressure to mimic real-life gusts.

A pass is when the screen and all parts remain whole: no rips, no separation, no alteration of any sort that disrupts the screen’s performance. 🧠 Why It Matters to You as a Homeowner You know those videos of a garage door collapsing and the roof flying away? That’s not just bad luck. It’s failed wind pressure resistance.

A screen that is badly made or not well fitted acts like a sail. After it gives, the storm gets inside — and the pressure destroys your home from the inside out. Which is why Florida Living Outdoor only offers systems like MagnaTrack, which have been engineered and tested to the strictest of standards. Exclusive self correcting track keeps screen tight under wind load.

What to Ask Before You Buy When you are investing in a screened-in patio or lanai, here+s what to ask your installer:

“Does this meet TAS 202 or ASTM E330?” “What pressure rating is this screen designed for?”

“Are you performing wind load with engineer-certified mounting systems?” If they can’t respond, move on.

💬 The bottom line: It Isn’t Just About Surviving the Hit …

It’s about standing strong after the hit, when the storm won’t stop. At Florida Living Outdoor, we handle each and every screen installation we do as if we are building a hurricane survival system. Because in Florida, it’s not if the wind blows … it’s when. ✅ Coming Next in Article 5: “Cyclone Cycles: What It Means to Pass a 9,000-Cycle Test” (Where we get into the repetitive impact/wind cycle testing — exhaustion tests for race cars.)

Find Out More or Schedule a Consultation Go visit how Florida Living Outdoor can help transform that Florida outdoor space into not just a little more usable — but a whole lot safer.

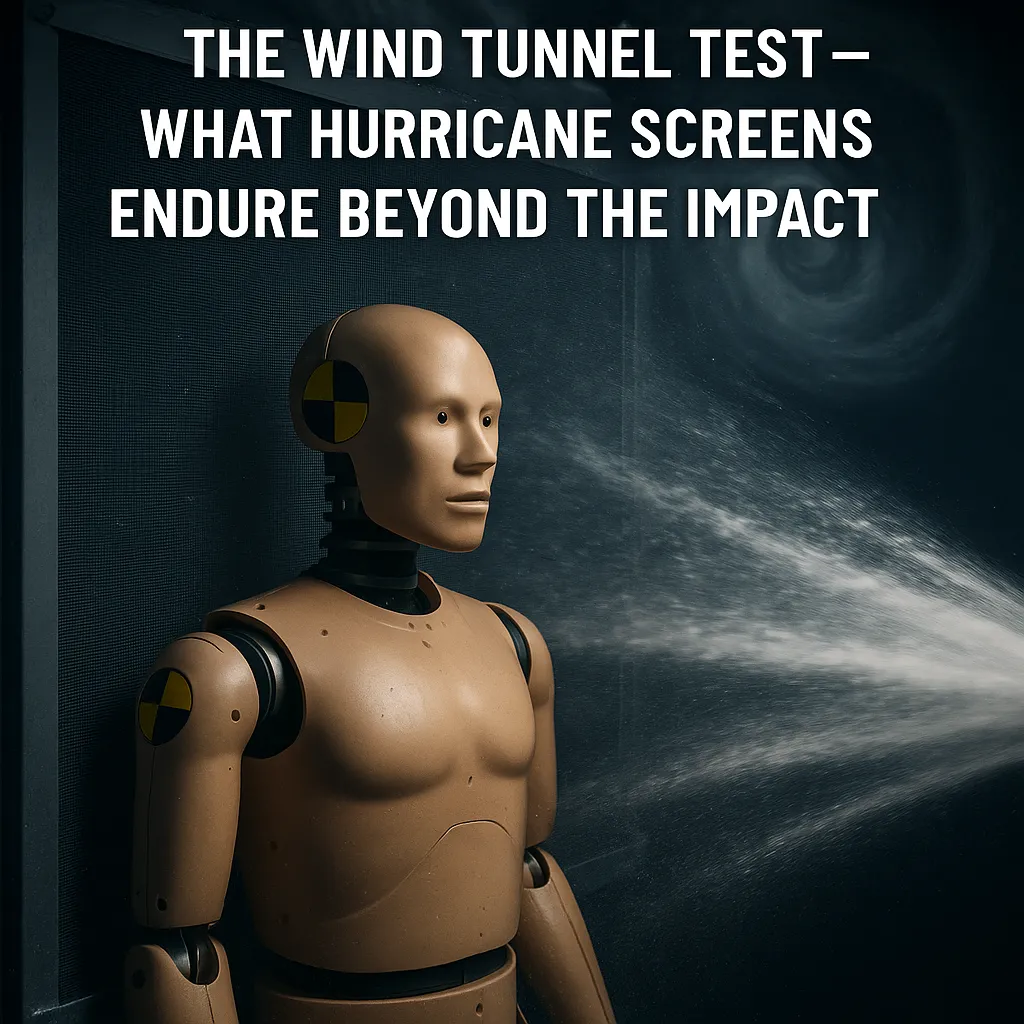

Beyond Impact: Why Hurricane Screens Must Pass the Wind Load Test

Impact is the Wrecking Ball, Wind Pressure is the Hurricane’s Breath.

You’ve seen how hurricane screens get pounded like car hoods in a crash test. But here’s the next question: What comes in the wake of the hit — when the storm continues to push? That’s where wind pressure testing comes in. The same way engineers of automobiles run tests to see how doors will fare in a rollover, screen makers simulate hours of hurricane-level winds to determine whether their product buckles, bows, buckles or blows apart. The standard? TAS 202 or ASTM E330. Consider it a wind tunnel test for your screen.

🚗 Analogy Time: Crash Test Dummies in a Wind Tunnel Think about it:

You take a car, put it in a wind tunnel and then, for 30-minute increments, you hit it with hurricane gusts, not a brief 5-second burst. That’s what TAS 202 simulates: Positive pressure: pushing the screen in, as the wind would the front of your house.

Negative pressure: sucking the screen outward (wind blowing past and pulling and from behind; this is roof-ripping wind). Your screen needs to do more than survive an impact — it needs to continue to perform intense pressure. No fluttering. No blowouts. No detachment from the frame.

🔬 Deconstructing TAS 202 / ASTM E330 TAS 202 is the reference cited by the Florida Building Code for testing of wind pressure.

ASTM E330 is the domestic equivalent of the structural performance of windows, doors and hurricane screens. Here’s what they test:

Air pressure loading corresponding to Category 5 hurricane winds (or custom design pressures).

Alternating positive and negative pressure to mimic real-life gusts.

A pass is when the screen and all parts remain whole: no rips, no separation, no alteration of any sort that disrupts the screen’s performance. 🧠 Why It Matters to You as a Homeowner You know those videos of a garage door collapsing and the roof flying away? That’s not just bad luck. It’s failed wind pressure resistance.

A screen that is badly made or not well fitted acts like a sail. After it gives, the storm gets inside — and the pressure destroys your home from the inside out. Which is why Florida Living Outdoor only offers systems like MagnaTrack, which have been engineered and tested to the strictest of standards. Exclusive self correcting track keeps screen tight under wind load.

What to Ask Before You Buy When you are investing in a screened-in patio or lanai, here+s what to ask your installer:

“Does this meet TAS 202 or ASTM E330?” “What pressure rating is this screen designed for?”

“Are you performing wind load with engineer-certified mounting systems?” If they can’t respond, move on.

💬 The bottom line: It Isn’t Just About Surviving the Hit …

It’s about standing strong after the hit, when the storm won’t stop. At Florida Living Outdoor, we handle each and every screen installation we do as if we are building a hurricane survival system. Because in Florida, it’s not if the wind blows … it’s when. ✅ Coming Next in Article 5: “Cyclone Cycles: What It Means to Pass a 9,000-Cycle Test” (Where we get into the repetitive impact/wind cycle testing — exhaustion tests for race cars.)

Find Out More or Schedule a Consultation Go visit how Florida Living Outdoor can help transform that Florida outdoor space into not just a little more usable — but a whole lot safer.

Products

Resources

For Professionals

Connect

© 2025 One Track - Powered by Fenetex and Friends of Oatis | Privacy Policy | Terms of Service

Products

Resources

For Professionals

Connect

© 2025 One-Track - Powered by Fenetex and Friends of Oatis | Privacy Policy | Terms of Service